Description

Cutback bitumen SC-70 is a slow curing bitumen that contains 50% bitumen. This bitumen is black in color and is produced under the ASTM D 2026M-15 standard.

Cutback asphalt can contain between 12 and 40 percent distillate. The high demand for the distillates to be used in energy applications and ever-increasing air quality regulations have caused a steady decline in the use of cutback asphalt.

Current common uses are in penetrating prime coats and in producing patching or stockpile mixtures. Cutback asphalt used in mixing with aggregate will usually contain an adhesion agent to assist in the coating of the aggregate surface.

Applications of Cutback bitumen SC-70

- capillary cavities

- plug capillary voids

- waterproofing of surfaces

- ideal for prime coat and cold applied

- coat and bond loose mineral particles

- covering and bonding loose mineral particles

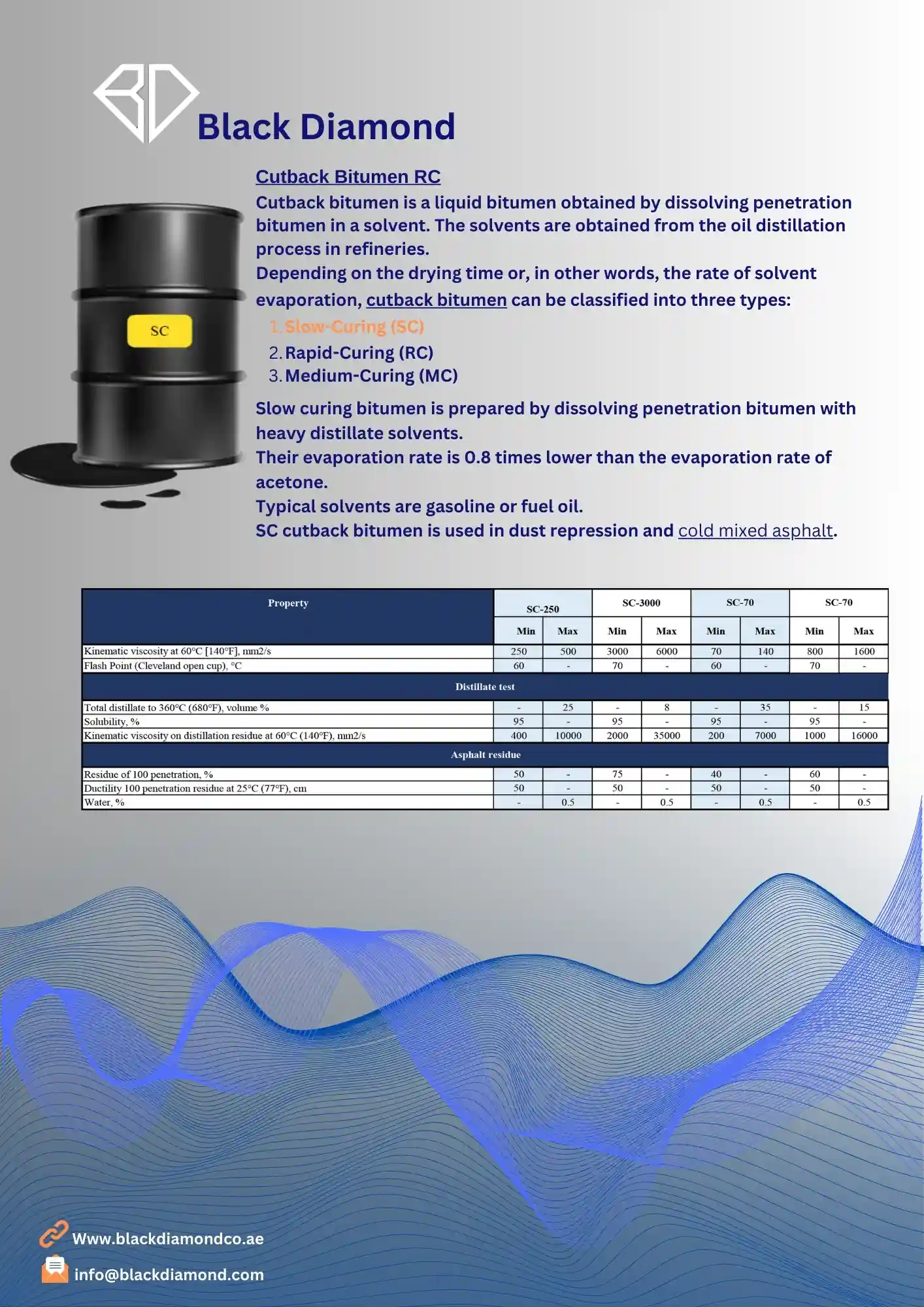

Specification of Cutback bitumen SC-70

| property | specification limit | Test method | |

| Min | Max | ||

| Kinematic viscosity at 60°C [140°F], mm2/s | 70 | 140 | ASTM D2170 |

| Flashpoint(Cleveland open cup), °C [°F] | 60 | — | ASTM D92 |

| distillate test | |||

| Total distillate to 360°C [680°F], volume % | — | 35 | ASTM D402 |

| Solubility, % | 95 | — | ASTM D2024 |

| Kinematic viscosity on distillation residue at 60°C [140°F], mm2/s | 200 | 7000 | ASTM D2170 |

| Asphalt residue | |||

| Residue of 100 penetration, % | 40 | — | ASTM D243 |

| Ductility of 100 penetration residue at 25°C [77°F], cm | 50 | — | ASTM D113 |

| Water, % | — | 0.5 | ASTM D95 |

Reviews

There are no reviews yet.